October 16, 2006 to-do list:

Things are starting to get a bit overwhelming for me. I tend to get ahead of myself and end up second-guessing, blue-skying, and just plain day-dreaming. In other words, I stall out until I can procrastinate no longer and I end up doing marathon sessions. In an effort to prevent that from occurring this time, I have decided to create a to-do list and try to link any dependencies so I can see the forest and the trees.

Note not listed by priority.

1. Build some cables and a break out board.

Status: The parts for the cables has been ordered and should be here by Wednesday. I have a PCB protoboard from Radio Shack but it may be too small.

2. Make a sample of the contest board and line for testing.

Status: Not started. Not a high priority but will need it when I test line sensors.

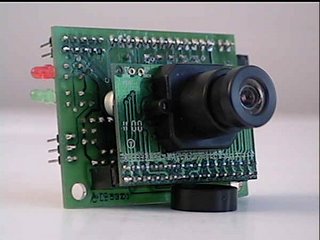

3. Make a line sensor and test different parts and configurations.

Status: I have QRD1114 and QRB1114 parts and can either feed them into the A2D or to digital I/O via an inverter. I have used both and am leaning towards the A2D.

Dependency: Maybe on wire making parts … but not required for prototypes

4. Make a terminal serial cable for debugging with AvrX

Status: Need to get a surplus serial cable. Then just connect the wires to the MAVRIC. I’ll search for one at lunch.

5. Rebuild/build H-bridge circuit.

Status: I have my original (5 years old now) Allegro Micro A3952SB circuit board and some of the newer

A3959SB parts. I need to redo the circuit with cleaner wiring.

Dependency: Wire making parts

6. Design the shape and size of the robot.

Status: I found this

link to a website that let’s you print your own graph paper. Will start sketching some designs for the wheel layout and base shapes

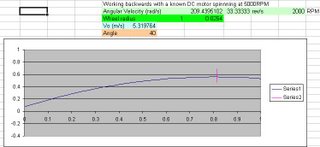

7. Design the motor mounts and encoder mounting

Status: Currently I have a tank-based mobile platform with the encoders serving as the other end of the tank tread. I will need to design a way to transfer the shaft motion to the encoders without interfering with the wheels. Also, I’d like the make the motor/encoder mount as a module that can be removed/installed as a component incase I ever want to change the base shape/layout.

8. Prototype a circuit that will decode the 1200Baud I/R signal.

Status: No started but do plan to use one of the UARTs on the MAVRIC. Have not decided on photodiode or phototransistor and will need to do some prototyping.

9. Add sound/speech.

Status: Have ordered components but am backordered on actual voice chip. No ETA. Will call manufacturer to get their opinion and may switch to competing product depending on timeline.

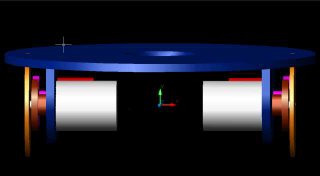

10. Build ball launcher.

Status: I have a pretty good idea for the design using a PVC elbow,

a brushless DC motor (because I have one), and

BLDC controller using a servo output. At this point I don’t have any real size constraints. The module should be sell contained and thus make it easy for me to change position and angle of it. At this point I am looking for the launcher to sit on one side of the robot.

Onward,

Jay